The torch can be quickly changed, no tools required.

The powder coat finish provides a harder, more resistant surface for protection The wrap around roll bar protects the case from damage resulting from shocks and collisions. The innovative case design is the result of extensive stress testing and field evaluations.

#Cigweld comweld 965 soldering flux msds portable#

The CUTMASTER™ is built for hard outdoor use as a portable plasmaĬage protects the controls, torch connection and air regulator.Ĭutter. CUTMASTER™ units are designed to stand up to the toughest environments and continue to provide precise, reliable cutting power.īuilt for Heavy Duty Operation The CUTMASTER™ range are designed with high duty cycles, tropical proofed Rugged Case Design The complete CUTMASTER™ range is engineered and tested to the highest standards of safety and reliability for plasma cutting equipment. Setting the standard in performance, value and reliability.

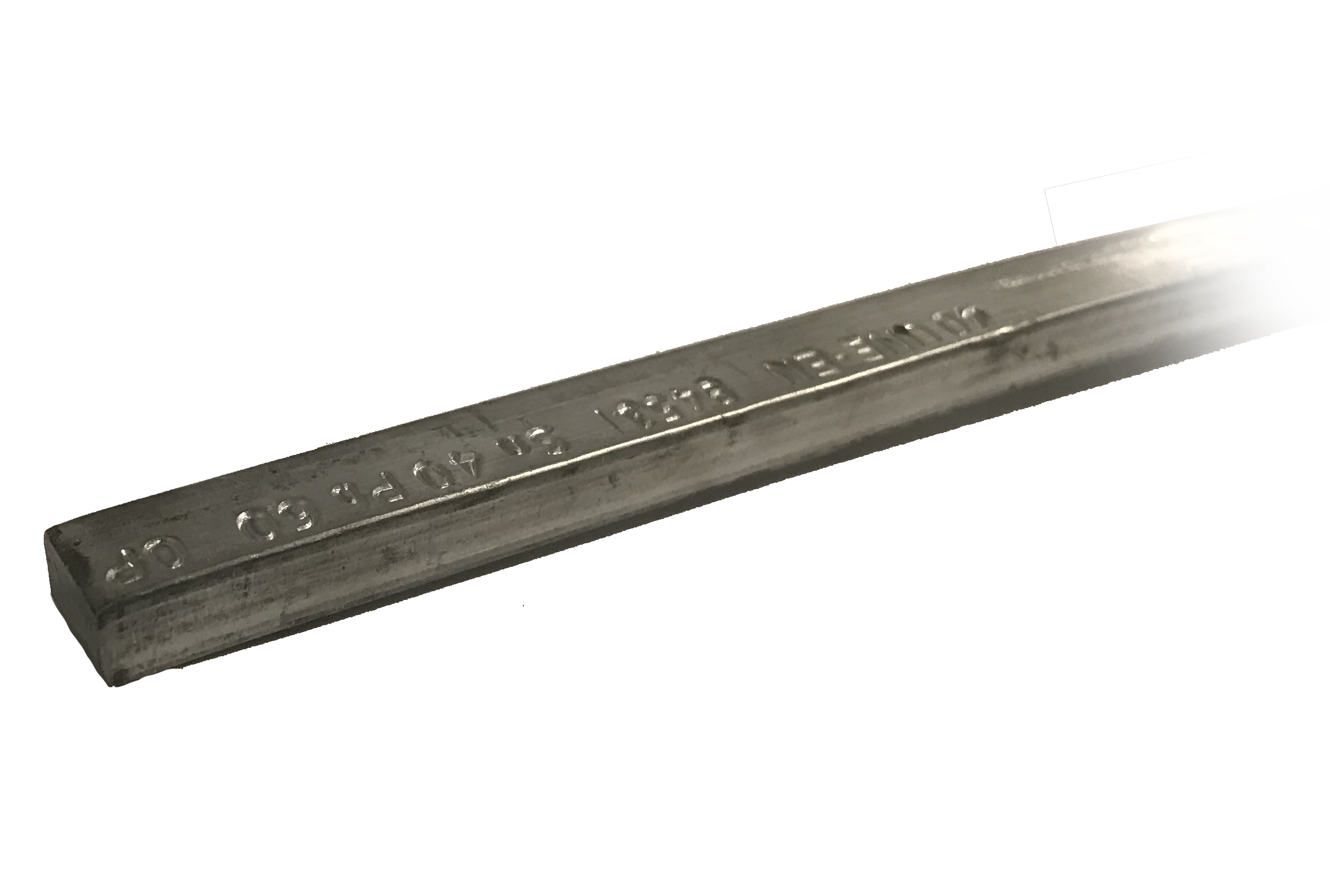

So read on for more information on how Thermal Dynamics® Cutmaster™ Systems can revolutionise your plasma cutting and gouging requirements. An advanced powder coat finish provides scratch and mark resistance to the case surface. All power sources have wraparound roll bars to protect them during transportation and whilst on the job. Built to stand up to rugged environments the Cutmaster™ units are tough and reliable. The 1Torch™ can also be retrofitted to virtually all existing plasma cutting systems on the market. All Cutmaster™ systems feature the revolutionary 1Torch™ plasma torch with the ATC™ (Advanced Torch Connector) quick disconnect, as well as new Arc start technology that eliminates electronic interference and provides optimal starting every time. Each model is suitable for cutting materials including mild steel, aluminium and stainless steel in industrial applications ranging from construction to fabrication to manufacturing. The Thermal Dynamics® Cutmaster™ Air Plasma Cutting Systems provide a complete range of machines for almost any air plasma task.

0 kommentar(er)

0 kommentar(er)